XGN-Z series heavy hammer Crusher

The XGN-Z series heavy hammer crusher is a new type of hammer crusher developed according to the user feedback information and the development dynamic development of the broken industry, the crushing function is comprehensive and in the case of suitable mineral physical properties (less than 600 tons),you can get crushed+integer, which has significant advantages such as large-scale granularity, high crushing ratio, and excellent granular type,the time is 150-6000 tons,the specifications are complete and can be customized on demand.

Applicable materials:It is suitable for crushing brittle materials such as limestone and bluestone with crushing compressive strength ≤ 150MPA and calcium content ≥ 40

Scope of application:Widely used in crushing operations of medium hard materials in mines, gravel fields, cement plants, construction, metallurgy and other industries.

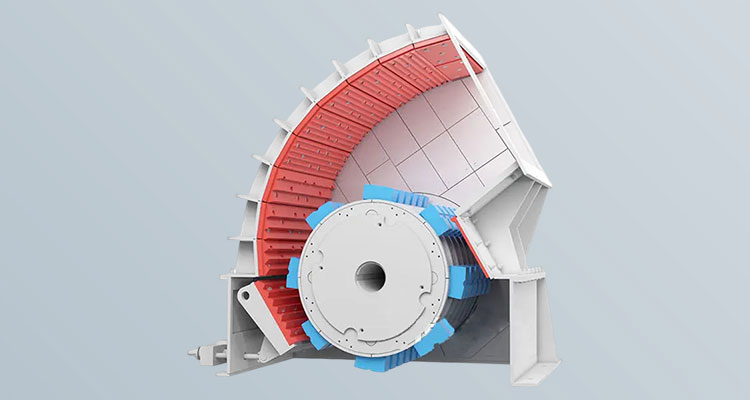

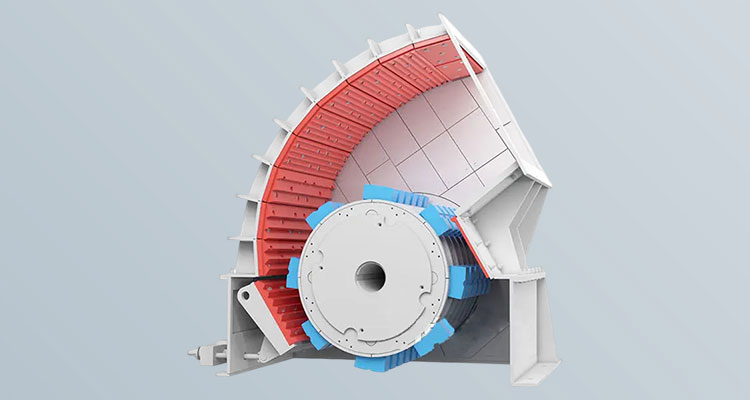

Internal Structure:It is mainly composed of the case, rotor, spindle, hammer head, lining, etc.

1、Large production capacity

The maximum feed particle size can reach 1800mm, the crushing ratio is large, and the output can reach 6000 tons per hour.

2、Low investment cost

With an output of less than 600 tons per hour, it can replace the jaw crusher + impact crusher. Under the same output, the investment is about 35% lower than that of jaw crusher + impact crusher.

3、High quality of finished products

sections of crushing, 7 heavy craftsmanship, perfect granules and reasonable levels; the unique self -flow slot design of the liveliper plate greatly reduces the powder rate.

4、Long service life

The whole machine is wear -resistant and resistant to the metal material, which effectively reduces the maintenance time of the shutdown; the counterattack plate 4 is fixed, the lining plate inside the case is tightly arranged and fixed by the 10.9 -level high -strength square, ensuring that the case is strong.

5、Wear-resistant Durable

Unique patented rotor disk wear-resistant retaining ring technology, high chromium alloy double-liquid compound hammer head, wear-resistant and easy to replace; 4-way 8 hammer shaft hole design, effectively prolonging the life of the rotor disk.

6、Reasonable structure

The back of the back, the double nut is fixed, stable and reliable; the independent shields+hydraulic shaft disassembling patents, saving time and effort, easy to change the hammer head; hydraulic counterattack rack, freely adjust the gap between the village board to the hammer head.

The motor drives the rotor at a high -speed rotation in the crushing cavity,the material is given the machine from the material from the upper part,the grain level of the size of the material than the size of the sieve hole is discharged through the sieve plate, and the coarse granular levels greater than the size of the sieve holes are stranded on the sieve plate to continue to be hit and grinded by the hammer,finally, the sieve plate is discharged outside the crusher The gap between the bar is adjusted.